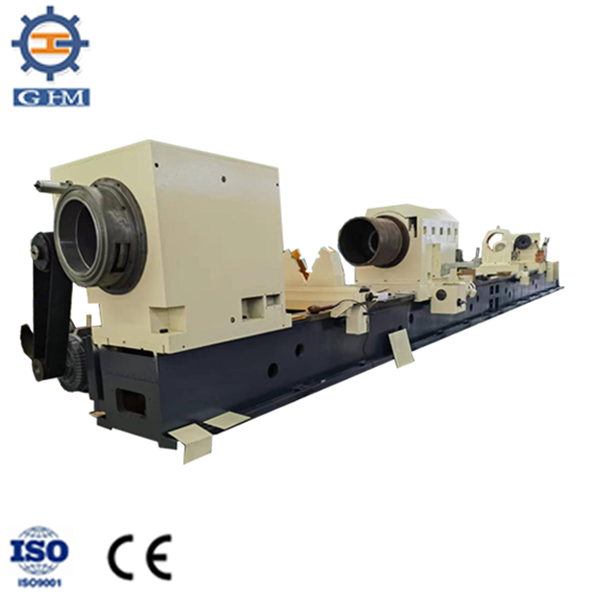

TGK2250 CNC Skiving roller burnishing machine

The TGK2250 CNC deep hole Skiving roller burnishing machine adopts the scraping rolling process for precision machining of various cylinder bore surfaces. It can also be used for combined boring scraping rolling processing of hot-rolled cylinder tubes. Its machining aperture accuracy is IT7-IT10 level, and the surface roughness is not greater than Ra0.2-0.4 μ m.

The TGK2250 CNC deep hole Skiving roller burnishing machine adopts a machining method of workpiece fixation and tool rotation feed. The bed adopts double rectangular guide rails, and the oil feeder is controlled by hydraulic pressure to position and release the workpiece, and quickly retracts axially through the motor. Adopting the hydraulic station in Yongzhen, Taiwan. The cooling system adopts an above ground oil tank structure, and the filtration method adopts a chip conveyor magnetic separator filtration method. The machine tool is equipped with a German SIEMENS CNC system, and the drag plate adopts gear rack feed and fast movement. The machine tool is equipped with high-efficiency automatic expansion and contraction combination cutting tools, and its machining efficiency is 3 to 5 times that of traditional deep hole machine tools.

Product application

Applied to aerospace, automotive manufacturing, oil and gas pipelines, lifting equipment, gun pipelines, bearings and other manufacturing industries.

We can customize according to your requirements.

technical parameter | TGK2250(1-8m) |

|---|---|

Bore diameter range(mm) | 200-500 |

Maximum depth of boring hole(mm) | 500-8000 |

Machine tool guide rail width(mm) | 755 |

Center height (from flat guide rail to spindle center)(mm) | 650 |

Range of feed rate(mm/min) | 10-3500 stepless |

Main motor of boring bar box | N=75kW CTB communication spindle motor |

Spindle box speed range(r/min) | 10-500 Two speed stepless |

Workpiece clamping range(mm) | 250-625 |

feed motor | N=7.5kW Communication servo motor |

Numerical Control System | SIEMENS 808 |

Hydraulic pump motor | N=2.2kW n=1440r/Min |

Cooling pump motor | N=11kW n=1440r/Min |

Rated pressure of cooling system(Mpa) | 0.6 |

Cooling system flow rate(l/min ) | 100-1500 |

French

French Spanish

Spanish Portuguese

Portuguese German

German Japanese

Japanese Korean

Korean