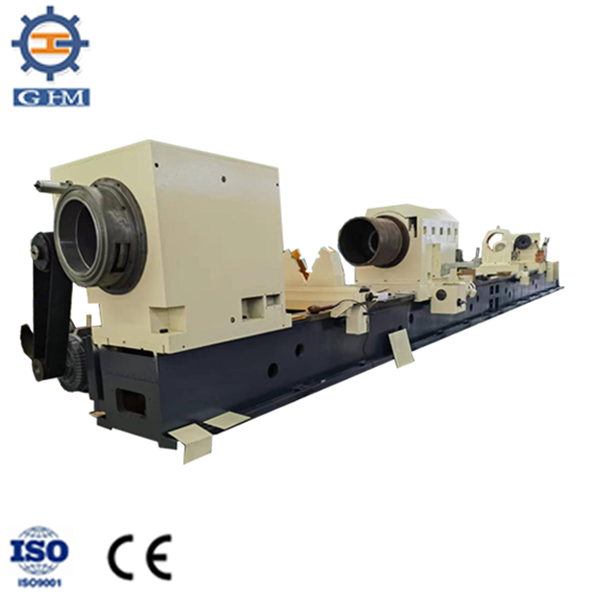

TGK2225 CNC Skiving roller burnishing machine

TGK2225 CNC Skiving roller burnishing machine is newly developed by our company.This machine has the smart and simple CNC operation system with high efficiency and stable performance,the configuration design is uniform,artistic and clean,using the environmental protection measures against oil splash and leakage.When processing,the workpiece is fixed and the tool is rotated.Adopting the combined technology of skiving and roller burnishing ,the machine gives a good solution for the severe deviation in rough processing of hot roller steel tube,and the inferior straightness in fine processing of cold drawn steel tube.It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder part.The hole tolerance is up to IT7-8,the surface roughness is up to Ra0.2-0.4 um.Its processing efficiency is 10 times of the traditional boring technology and 20 times of ordinary honing machines.The traditional technology usually includes four independent steps in order:rough boring-semi fine boring-floating boring-roller burnishing,which is inefficient and needs a long time.

Product application

Applied to aerospace, automotive manufacturing, oil and gas pipelines, lifting equipment, gun pipelines, bearings and other manufacturing industries.

We can customize according to your requirements.

Bore diameter range (mm) | 35~250 |

Maximum depth of boring hole (mm) | 500~2000 |

Machine tool guide rail width (mm) | 600 |

Center height (from flat guide rail to spindle center) (mm) | 400 |

Range of feed rate (mm/min) | 10-3500 (Stepless) |

Main motor of boring bar box (kW) | N=60 CTB communication spindle motor |

Range and stages of drill rod spindle speed (r/min) | 60-1200 Two speed stepless |

Workpiece clamping range (mm) | 100-350 |

Feed motor | N=7.0kW servo motor |

Control System | SIEMENS 808D |

Hydraulic pump motor | N=2.2kW |

Cooling pump motor | N=7.5kW N=1440r/min 2 groups, 1 group adopts frequency conversion control |

Rated pressure of cooling system (Mpa) | 0.6 |

Liquid extraction pump motor | N=11kW N=1440r/min 2 groups |

Cooling system flow rate (l/min) | 100-800 |

French

French Spanish

Spanish Portuguese

Portuguese German

German Japanese

Japanese Korean

Korean