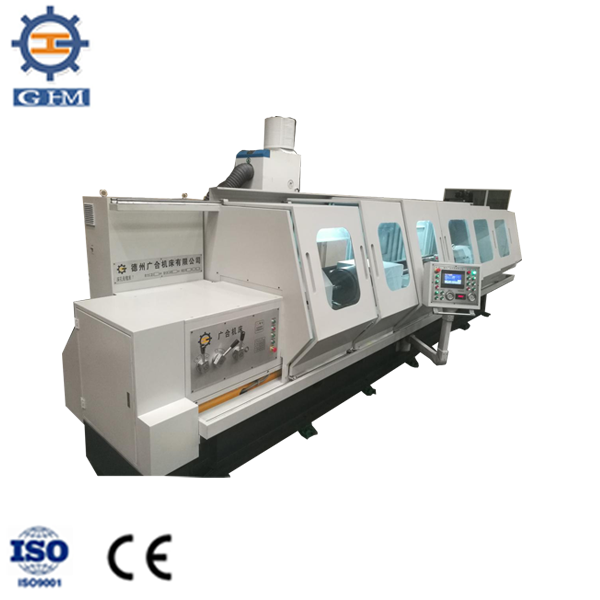

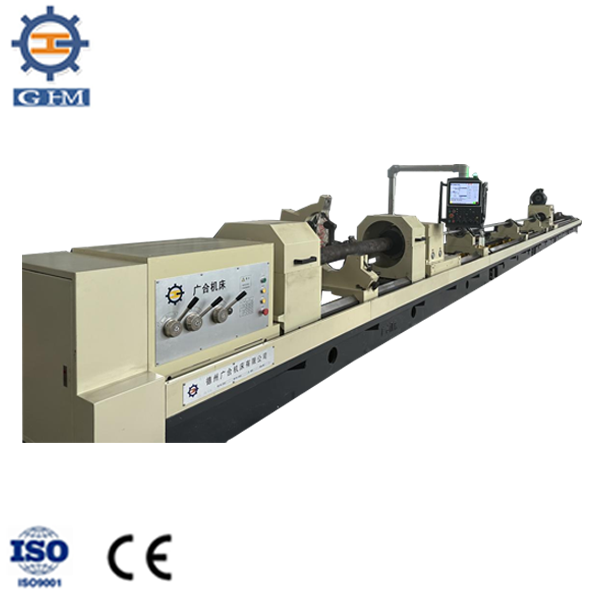

TK2242 CNC Deep hole drilling and boring machine

Video Description

TK2242 CNC Deep hole drilling and boring machine uses drilling,boring, scraping-rolling technology to precisely process the inner hole surface of various cylinder barrels, The machine tool is fixed by the workpiece and the tool is rotated and fed. The working efficiency is many times that of the traditional machine tool.

1. The machine tool is required to have the tool monitoring function, when the tool is excessively worn or the blade breaks, the machine tool can stop in time and alarm.

2. Mechanical damping drill pipe support device with rotary tool is adopted. The fit between the shock absorbing support sleeve and the drill pipe can be adjusted by rotating the jacking nut to better reduce the vibration and guidance of the drill pipe.

3.Equipped with lighting, equipped with self-locking mobile security door. Plexiglass Windows are provided to facilitate observation of machine processing. The machine is sealed well, and no leakage occurs.

We can customize according to your requirements.

Drilling diameter range(mm) | 50~420 |

Maximum depth range of boring hole(mm) | 1000~10000 |

Chuck diameter(mm) | 325 |

Central frame clamping diameter range(mm) | 20~180(Standard configuration) |

Main spindle speed range and stages | 70~1200r/min |

Main motor | N=15kW |

Range of feed rate(mm/min) | 5~2000 stepless |

Feed motor | N=4.5kW servo motor |

Oil feeder motor | N=4.5kW servo motor |

Cooling pump motor | N=5.5kW Two groups |

Rated pressure of cooling system(MPa) | 2.5、6.5 |

Cooling system flow rate(L/min) | 80 180 |

French

French Spanish

Spanish Portuguese

Portuguese German

German Japanese

Japanese Korean

Korean