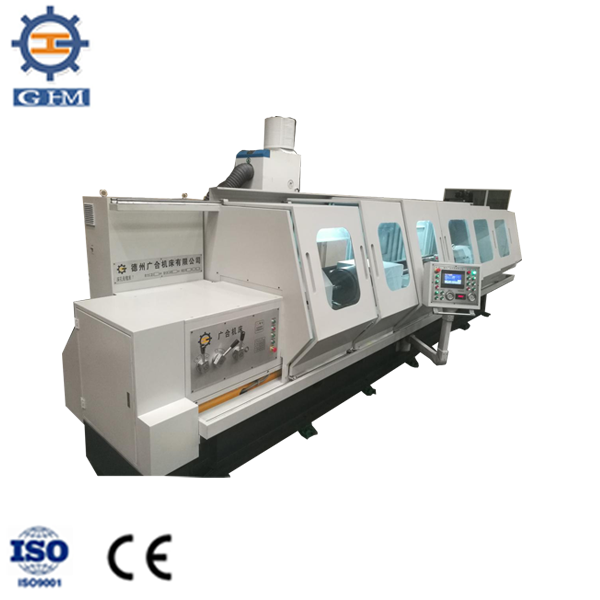

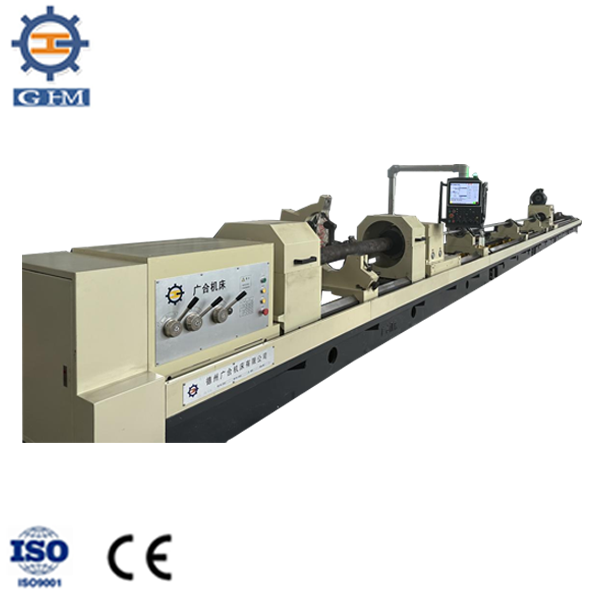

TZK06-70 deep hole drilling and boring machine

The structure of TZK06-70 deep hole drilling and boring machine mainly includes bed body, headboard box, chuck body and chuck, center frame, workpiece bracket, oil feeder, drilling and boring bar shock absorber bracket, feed drag plate and drill pipe box, chip hopper, cooling system (high-pressure oil supply system and oil tank, chip processing device), control system, etc.

The TZK06-70 deep hole drilling and boring machine is suitable for deep hole drilling, boring, and rolling processing of workpieces. During processing, the workpiece rotates, the tool rotates and feeds. The BTA internal chip removal process is used during drilling; When boring, the process of discharging cutting fluid and chips forward (in the headstock) or backward (inside the drill pipe) is adopted.

There are two ways to process TZK06-70 deep hole drilling and boring machine:

1. The workpiece and tool rotate in opposite directions simultaneously, and the drill pipe box drives the tool to feed;

2. Workpiece rotation, tool feed does not rotate;

This KT series machine tool is suitable for steel machining and widely used for deep hole machining of automotive parts, coal mine hydraulic supports, hydraulic cylinders, motor spindles, high-speed train axles, shipbuilding industry, chemical machinery, weapon industry machinery manufacturing, aerospace machinery manufacturing and other parts.

We can customize according to your requirements.

Machine tool model | TZK06-70 |

Processing tools | BTA drill bit, boring head, rolling head |

Workpiece clamping method | Chuck clamping and cone disk tightening |

Local machining method | Reverse rotation of workpiece and tool |

Number of spindles | 1 |

Drilling hole diameter range | 6-70mm |

Maximum drilling and boring depth | 1000mm |

Spindle center height | 350mm |

Diameter range of workpiece support bracket | 30-200mm |

Central frame clamping diameter range | 30-200mm |

Drill pipe box motor power | 22kW |

Headboard box motor power | 30kW |

Range of spindle speed for drill pipe box | 0-1500rpm,2nd gear, continuously variable transmission within gear |

Headboard spindle speed range | 20-400rpm,2nd gear, continuously variable transmission within gear |

Feed speed range (stepless) | 5-500 mm/min |

Fast forward speed | 2000mm/min |

Numerical Control System | Siemens 828D |

Feed servo motor torque | 27Nm |

Hydraulic system motor power | 2.2kW |

Maximum pressure of cooling system | 70 bar |

Maximum flow rate of cooling system | 240 L/min |

Cooling oil pump motor power | 22kW |

Precision of cutting oil filtration | ≤30μm |

Fuel tank capacity | 2000L |

Total power of the switchboard | 80kW |

supply voltage | 3AC 380V ±10% |

frequency | 50Hz |

control voltage | 24V |

Machine tool footprint (length * width * height) | 6000*3000*1600 |

Machine weight (approximately) | 10t |

French

French Spanish

Spanish Portuguese

Portuguese German

German Japanese

Japanese Korean

Korean