French

French

Spanish

Spanish

Portuguese

Portuguese

German

German

Japanese

Japanese

Korean

Korean

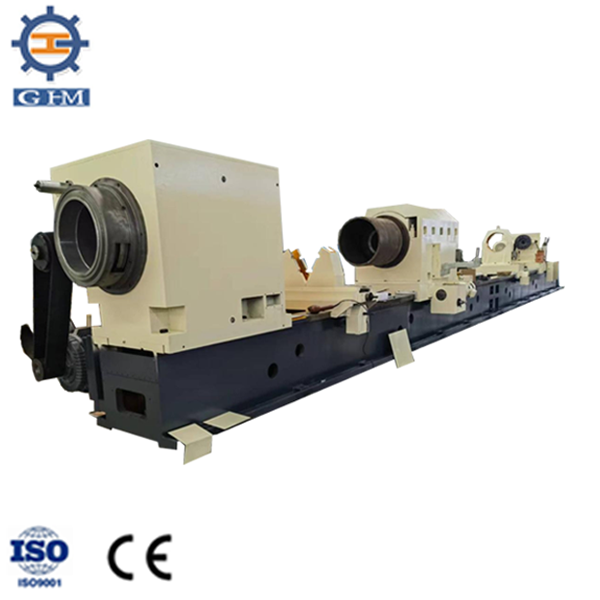

What are the functions of deep hole scraping and rolling machine tools

The deep hole scraping and rolling machine tool, as an important equipment in modern mechanical processing, mainly plays the following roles:

一、 Efficient precision machining

Through two processes of scraping and rolling, efficient and precise machining of the inner wall of deep hole parts has been achieved. During this process, the machine tool can automatically complete the steps of scraping burrs and protrusions on the hole wall, smoothing the hole wall, and finely adjusting the hole wall, greatly improving machining efficiency and accuracy. Specifically, the machine tool is capable of controlling aperture accuracy within 0.01mm, meeting the high precision requirements of high-end manufacturing industries.

二、 Improve workpiece performance

During the machining process, a cold work hardening layer can be formed on the surface of the workpiece, which not only improves the wear resistance of the inner wall of the workpiece, but also helps to seal small surface cracks due to the residual compressive stress left on the surface layer, thereby improving the corrosion resistance and fatigue strength of the workpiece. This processing method effectively avoids the burn problems that may be caused by traditional honing processes and extends the service life of the workpiece.

三、 Widely applicable fields

Has a wide range of application fields, including but not limited to the following industries:

Hydraulic industry: used for processing the inner holes of hydraulic cylinders to ensure the sealing and service life of the cylinders.

Metallurgy and aerospace: Processing high-precision, high demand metal tube inner holes to meet the needs of complex working conditions.

Construction Machinery: Used for cylinder barrel processing of various types of construction machinery to improve equipment performance and reliability.

Oil and coal: In oil drilling and mining equipment and coal machinery, the inner holes of cylinder barrels are processed to withstand extreme conditions such as high pressure and high temperature.

In addition, this machine tool is also suitable for machining inner holes in various materials such as stainless steel pipes, copper pipes, and cast iron pipes. The machining diameter range is generally 50mm to 630mm, and the length can reach 500mm to 15000mm, meeting the machining needs of different specifications and materials.

四、 Promote the development of manufacturing industry

The emergence and widespread application of deep hole scraping and rolling machine tools not only improve the machining accuracy and efficiency of the manufacturing industry, but also promote the development of the manufacturing industry to a higher level. With the advancement of technology and continuous improvement of processes, the performance and applicability of scraping and rolling machine tools will be further enhanced, providing stronger support for the transformation and upgrading of the manufacturing industry and high-quality development.

In summary, deep hole scraping and rolling machine tool play a crucial role in modern mechanical processing. Their efficient and precise machining capabilities, improved workpiece performance, and wide range of application fields make them indispensable and important equipment in the manufacturing industry.

What industries are deep hole

What industries are deep hole

Customer Case of Alien Drillin

Customer Case of Alien Drillin

Deep hole honing machine proce

Deep hole honing machine proce

Precautions for using CNC deep

Precautions for using CNC deep