French

French

Spanish

Spanish

Portuguese

Portuguese

German

German

Japanese

Japanese

Korean

Korean

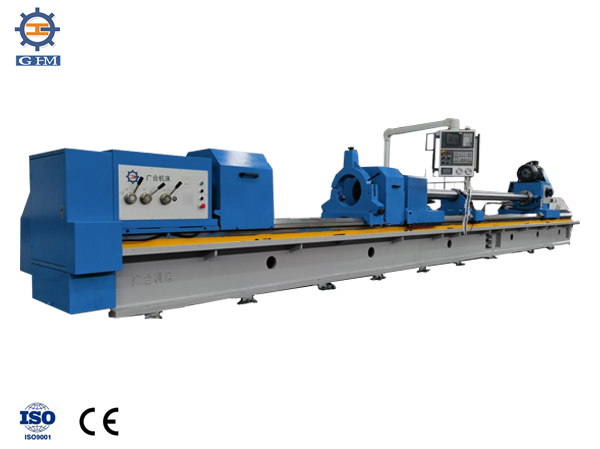

Working principle of deep hole drilling and boring machine

Deep hole drilling and boring machine is a specialized mechanical equipment used for processing deep holes. Its working principle is complex and precise, involving the collaborative action of multiple components. The following is a detailed explanation of the working principle of deep hole drilling and boring machines:

一、 Basic Composition

Deep hole drilling and boring machines are usually composed of key components such as bed, worktable, feed mechanism, spindle, and cooling system. These components together form a stable and efficient machining platform, ensuring the smooth progress of deep hole machining.

二、 Working principle

1. Spindle rotation and tool installation

The deep hole drilling and boring machine drives the tools (such as drill bits and boring tools) installed on the spindle to rotate through the rotation of the spindle. This is the basic power source for achieving cutting machining.

2. Feed mechanism control

The feed mechanism is responsible for controlling the feed speed and depth of the tool. During the machining process, the feed mechanism will precisely control the tool to feed into the workpiece according to the preset machining parameters, in order to achieve the desired machining depth.

3. Cutting process

When the tool rotates and feeds into the workpiece at the same time, the cutting edge of the tool will rub and squeeze against the workpiece material, thereby cutting off the workpiece material. Deep hole drilling and boring machines usually use the external chip removal drilling method, which means that the chips generated during the cutting process are discharged from the outside of the workpiece through the chip removal groove of the tool or a specialized chip removal system to maintain the cleanliness of the machining area and the sharpness of the tool.

4. Cooling and lubrication

In order to reduce friction and heat accumulation during the cutting process, protect the tool and workpiece from damage, deep hole drilling and boring machines are usually equipped with cooling systems. The cooling system achieves cooling and lubrication of the tool and workpiece by spraying coolant or lubricant into the cutting area.

5. Automated control

Modern deep hole drilling and boring machines also have the characteristic of high automation. Through programming and control systems, automatic adjustment of machining parameters, automatic monitoring of machining processes, and automatic diagnosis of faults can be achieved. This greatly improves processing efficiency and precision, and reduces the labor intensity of operators.

In summary, the working principle of deep hole drilling and boring machines is to drive the cutting motion of the tool through the rotation of the spindle, while the feed mechanism controls the feed speed and depth of the tool, supplemented by cooling and lubrication systems and automation control systems, to achieve efficient and high-precision machining of the workpiece.

Dezhou Guanghe Machine Tool Co., Ltd. is a company specializing in the research and development, production, and sales of high-precision deep hole machine tools. Our main products include CNC deep hole boring machines, deep hole drilling and boring machines, scraping and rolling machines, and deep hole honing machines. For detailed information, please feel free to leave a message online~

What industries are deep hole

What industries are deep hole

Customer Case of Alien Drillin

Customer Case of Alien Drillin

Deep hole honing machine proce

Deep hole honing machine proce

Precautions for using CNC deep

Precautions for using CNC deep